Underwater inspections have played a vital role in ensuring the safety and integrity of transportation infrastructure such as bridges, ports, piers, and pipelines.

Routine inspections can identify structural defects, corrosion, erosion, and other signs of deterioration that can compromise the stability and performance of structures. At the forefront of this process are divers, who employ a diverse array of techniques and tools tailored to the unique challenges posed by underwater environments. Over the years, inspections have evolved from rudimentary techniques to sophisticated methods, leveraging advancements in technology, engineering, and safety protocols.

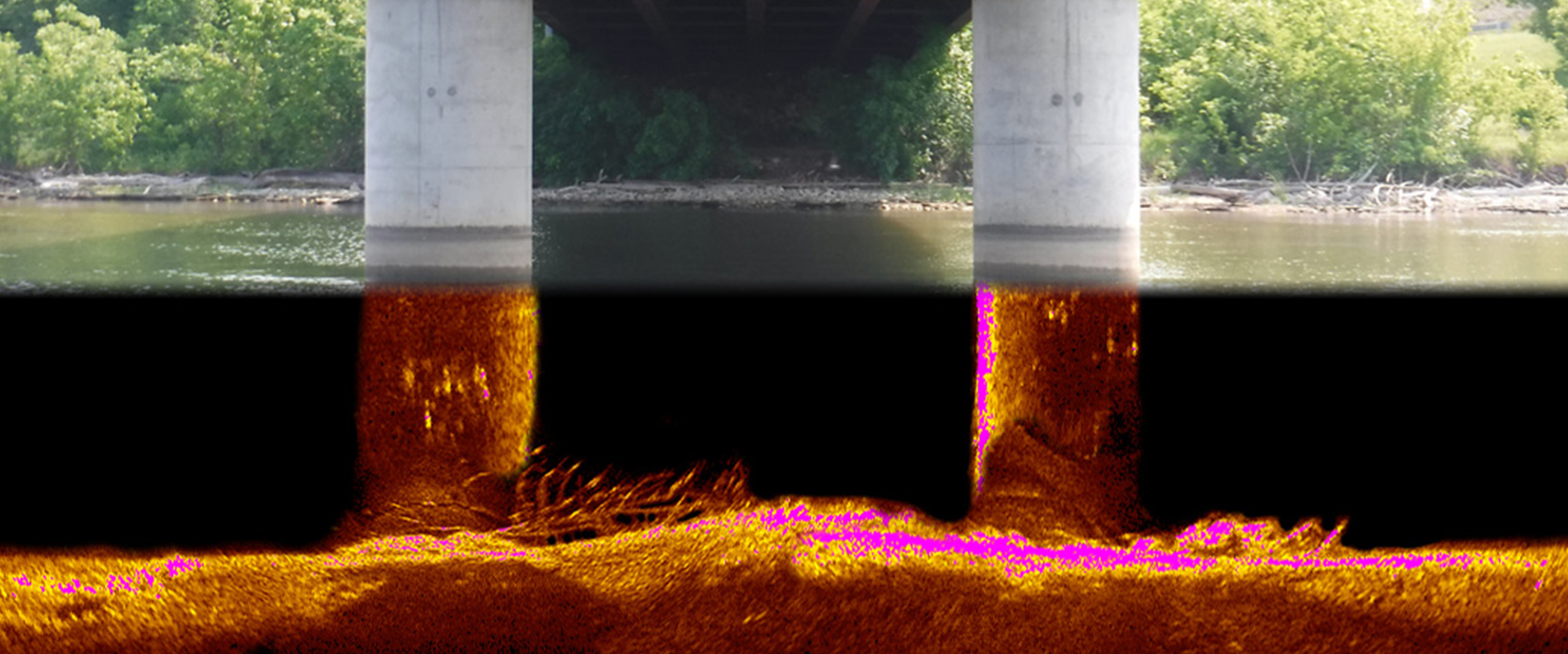

Traditional underwater inspections require direct human observation and physical examination of structures. To aid in these inspections, KCI’s team of divers have begun utilizing acoustic imaging technology, a non-destructive testing technique that uses sound waves to create detailed visual representations of underwater structures. When sound waves encounter an object, they are reflected back to the source, absorbed by the object, or scattered in different directions. By analyzing the characteristics of the reflected sound waves, the device can create images of the object.

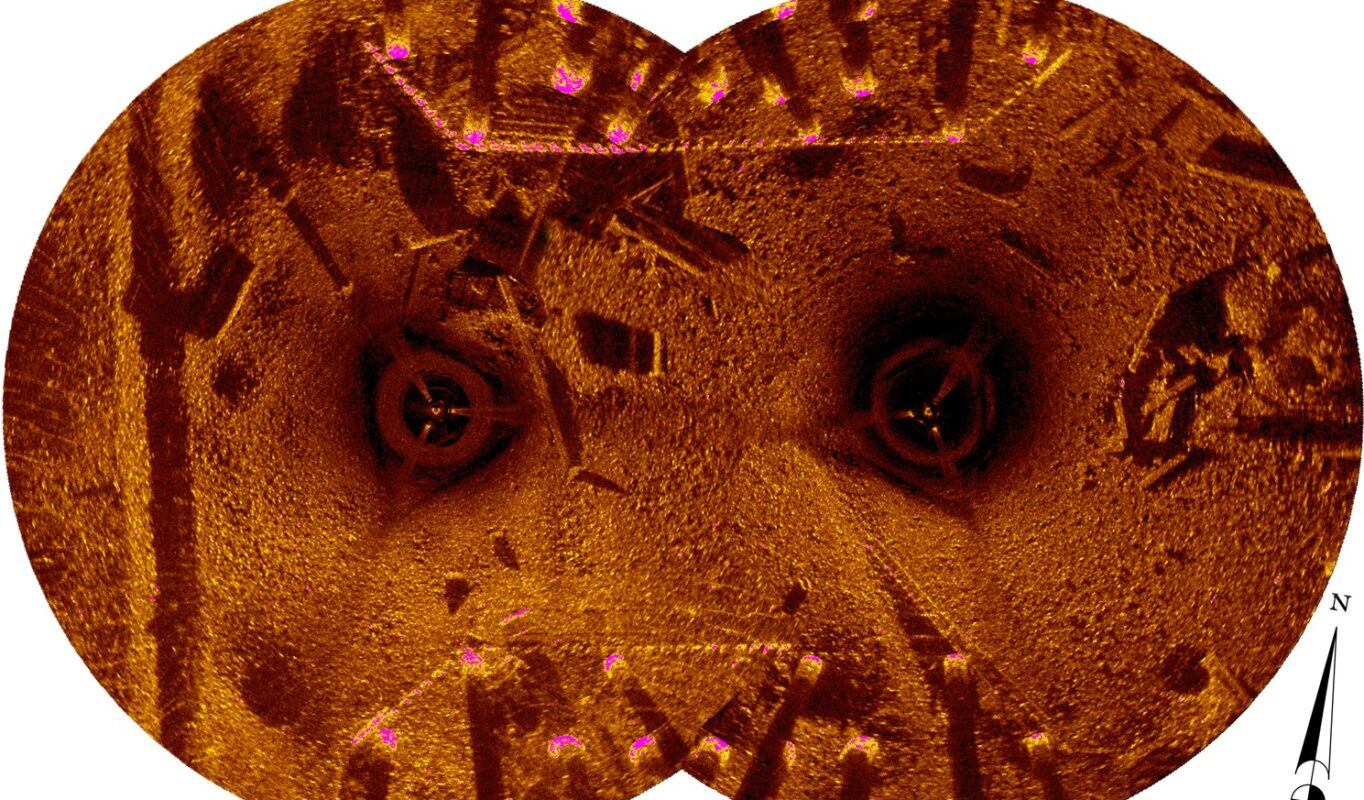

Mounted to the side of the boat, or dropped overboard on a tripod as shown, the sonar equipment can capture detailed images of the structures requested.

Mounted to the side of the boat, or dropped overboard on a tripod as shown, the sonar equipment can capture detailed images of the structures requested.As part of an on-call contract with the Missouri Department of Transportation, our team has completed several task orders including acoustic imaging of more than 30 piers in depths up to 90 feet for multiple bridges over the Lake of the Ozarks, as well as imaging for nearly a dozen bridges crossing the Mississippi and Missouri Rivers. In addition to traditional inspection methods, acoustic imaging was employed to define the condition of the underwater substructure units and the surrounding streambed. With this technology, inspections can easily penetrate through low visibility conditions to provide a clear image of submerged structures, helping to highlight damage or corrosion that should be further inspected via alternative methods.

By documenting inspections, the images and data can be stored and used for future reference to track changes over time or to communicate findings to stakeholders.

By documenting inspections, the images and data can be stored and used for future reference to track changes over time or to communicate findings to stakeholders. Additionally, acoustic imaging can aid in locating specific objects or verifying their absence. KCI’s divers employed this technology during a debris survey mandated by the Coast Guard after the construction of a new bridge in Maryland. Our team was able to confirm that there was no construction debris obstructing the navigation channel, ensuring safety for all waterway users, and mitigating any potential environmental risks.

This technology not only optimizes the inspection process by complementing visual and tactile methods, but also contributes to an elevated level of operational efficiency.

This technology not only optimizes the inspection process by complementing visual and tactile methods, but also contributes to an elevated level of operational efficiency.Acoustic imaging serves as a valuable tool for engineering dive teams, detecting potential issues and hidden hazards lurking in murky waters before they become major safety concerns. With real-time monitoring and a clear image of the underwater environment, the technology also enables dive teams to locate divers and provide directional commands even in low visibility conditions. In preparation for planned improvements to Interstate 30, the Texas Department of Transportation asked KCI to locate and mark existing AT&T cables in the lakebed of Lake Ray Hubbard. To ensure the diver’s underwater navigation and situational awareness, our team employed acoustic imaging to guide them in the correct direction as they moved from one utility to the next.

“A lot of our diving is done in low visibility water and this sonar system provides us with an elevated view, allowing us to see what is under the surface. This helps to make dives safer for our team by making us aware of concerns or directing divers to areas of focus.”

Stephen Reuschle, Practice Leader

Despite its usefulness as a supplementary tool, acoustic imaging is not intended to replace traditional underwater inspections; rather, it is designed to complement visual inspections and provide additional information. Although acoustic imaging offers a different perspective, human observations still play a critical role in the inspection process. Divers can detect subtle signs of damage and deterioration that may not be discernible through acoustic imaging alone, drawing on their experience and expertise to make informed judgments.

Nonetheless, the versatile range of applications for acoustic imaging devices are transforming the way divers work, providing invaluable support, and enhancing the accuracy, efficiency, and safety of underwater inspections. As technological advancements continue to progress, dive teams can look forward to even more improvements in their inspection capabilities.